In the realm of manufacturing, precision and efficiency are paramount. The evolution of Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of intricate components with unprecedented accuracy. Among the various CNC machining techniques, 5-axis CNC machining stands out as a pinnacle of precision and versatility. Let’s delve into the world of 5-axis CNC machining services and understand how they are redefining efficiency in manufacturing processes.

Understanding 5-Axis CNC Machining

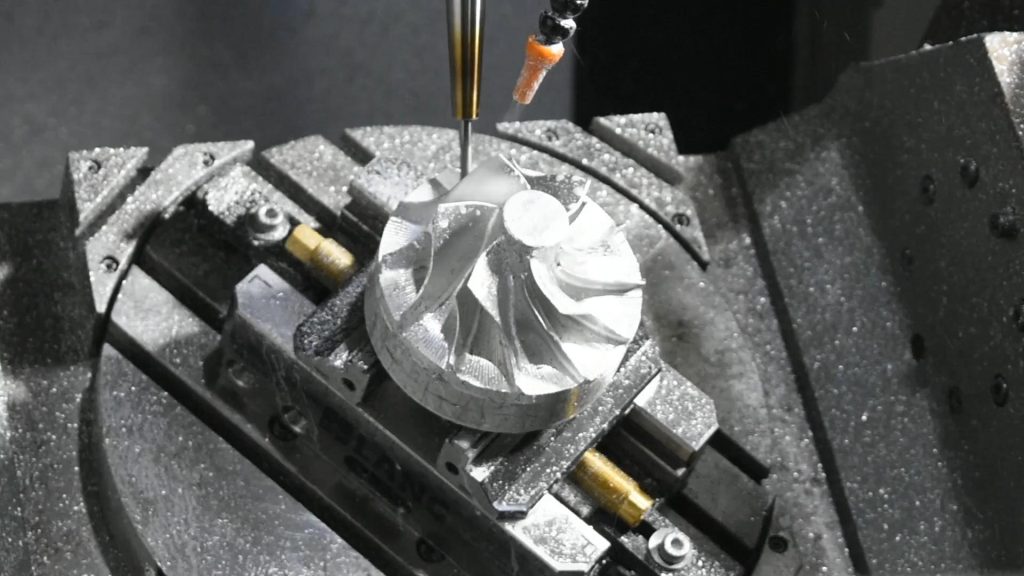

Traditional CNC machining operates along three axes: X, Y, and Z. This means that the cutting tool moves in three directions to create the desired shape. However, certain complex geometries, such as turbine blades, aerospace components, and medical implants, require machining from multiple angles. This is where 5-axis CNC machining comes into play.

5-axis CNC machining adds 5 axis cnc machining rotational axes to the traditional X, Y, and Z axes. These additional axes enable the cutting tool to approach the workpiece from multiple directions and angles, resulting in the ability to machine intricate shapes with a higher degree of precision and efficiency. With 5-axis machining, manufacturers can produce complex parts in a single setup, eliminating the need for time-consuming repositioning and fixture changes.

Advantages of 5-Axis CNC Machining Services

1. Enhanced Precision: One of the primary advantages of 5-axis CNC machining is its ability to maintain consistent accuracy across complex geometries. By allowing the cutting tool to access the workpiece from multiple angles, 5-axis machining minimizes the need for manual rework and ensures superior surface finish and dimensional accuracy.

2. Reduced Setup Time: Traditional machining processes often require multiple setups and fixture changes to access different features of a workpiece. In contrast, 5-axis CNC machining can complete complex parts in a single setup, significantly reducing setup time and minimizing the risk of errors associated with manual repositioning.

3. Improved Efficiency: The ability to machine complex parts in a single operation streamlines the manufacturing process and reduces overall production time. This increased efficiency not only accelerates time-to-market but also lowers production costs by minimizing labor and material waste.

4. Expanded Design Possibilities: 5-axis CNC machining opens up a world of design possibilities by enabling the production of highly intricate and organic shapes that would be challenging or impossible to achieve with traditional machining methods. This flexibility allows engineers and designers to unleash their creativity and innovate without being constrained by manufacturing limitations.

5. Versatility Across Industries: From aerospace and automotive to medical and defense, 5-axis CNC machining finds applications across a wide range of industries. Whether it’s producing lightweight aerospace components with complex contours or manufacturing patient-specific medical implants with precision, 5-axis machining offers unparalleled versatility to meet diverse manufacturing needs.

Applications of 5-Axis CNC Machining

The versatility of 5-axis CNC machining makes it suitable for a multitude of applications, including:

· Aerospace components: Engine parts, turbine blades, and structural components.

· Automotive parts: Prototyping, tooling, and complex engine components.

· Medical devices: Implants, surgical instruments, and prosthetics.

· Mold and die manufacturing: Complex molds for injection molding and die-casting applications.

· Defense and firearms: Tactical components and firearm accessories requiring intricate machining.

Conclusion

In an era where precision and efficiency are critical to staying competitive in the global marketplace, 5-axis CNC machining services emerge as a game-changer for manufacturers seeking to push the boundaries of innovation. By harnessing the power of multi-axis machining, companies can unlock new design possibilities, accelerate production timelines, and deliver superior-quality components with unmatched precision. As technology continues to advance, the role of 5-axis CNC machining in redefining efficiency in manufacturing processes will only continue to grow, shaping the future of industrial production.