Reverse engineering services have emerged as a pivotal tool in various industries, facilitating innovation, cost reduction, and improved product development processes. One sector where these services play a particularly crucial role is the automotive industry. In an era defined by rapid technological advancements, market competition, and the demand for cutting-edge features, automotive manufacturers are turning to reverse engineering to stay ahead in the race.

Understanding Reverse Engineering in the Automotive Industry:

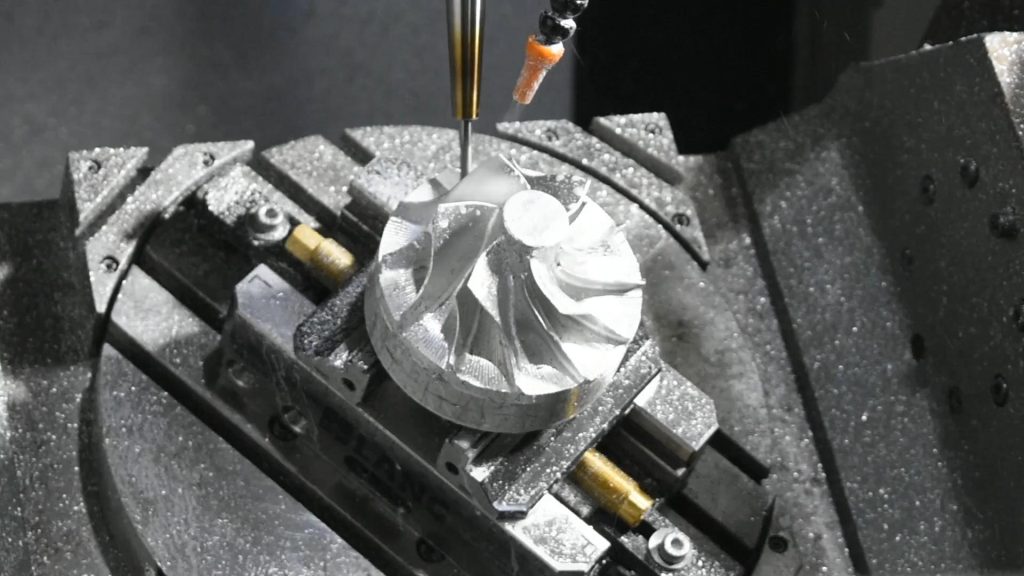

Reverse engineering involves dissecting a product or system to understand its components, functions, and interrelationships. In the automotive sector, this process is used to analyze the design and functionality of vehicles, their components, and even the manufacturing processes. The goal is to gain insights that can be utilized for various purposes, such as improving existing products, developing new ones, or ensuring compatibility with other systems.

Applications of Reverse Engineering in the Automotive Sector:

1. Product Improvement and Innovation:

Reverse engineering allows automotive companies to dissect competitor products, gaining a deeper understanding of their features, materials, and manufacturing processes. This knowledge can be used to enhance existing products, add innovative features, or even develop entirely new and improved models. For example, a car manufacturer might reverse engineer a competitor’s engine to identify design optimizations or efficiency improvements.

2. Legacy System Upgradation:

As technology evolves, automotive manufacturers often find themselves dealing with legacy systems that may not be compatible with modern advancements. Reverse engineering helps in updating these systems by understanding their architecture and integrating new technologies. This is especially crucial for older vehicles that need to comply with current safety and environmental standards.

3. Supply Chain Optimization:

Reverse engineering aids in analyzing the components of a vehicle, helping manufacturers identify potential cost savings. By understanding the makeup of each part, companies can explore alternative matrials or manufacturing processes that might be more cost-effective without compromising quality. This optimization extends to the entire supply chain, making production processes more efficient and reducing overall costs.

4. Customization and Modification:

Car enthusiasts often seek to customize or modify their vehicles. Reverse engineering provides a means to understand the existing design, enabling the creation of custom parts or modifications. This has given rise to a thriving aftermarket industry where companies can offer tailored solutions for vehicle enthusiasts.

5. Competitive Intelligence:

To stay ahead in a highly competitive market, automotive companies need to have a thorough understanding of their competitors. Reverse engineering helps in gaining insights into the latest technological advancements, design trends, and manufacturing processes adopted by rivals, allowing companies to make informed strategic decisions.

Conclusion:

In the fast-paced world of the automotive industry, staying ahead requires continuous innovation, cost optimization, and a keen understanding of market trends. Reverse engineering services have become an indispensable tool for automotive manufacturers, providing them with the means to dissect, understand, and improve upon existing products. By harnessing the power of reverse engineering, companies can unlock new levels of innovation, ensuring they remain at the forefront of an ever-evolving industry.